Knowledge Base

Paper Characteristics

-

What is Cold Pressed?Cold Pressed, or CP, is a paper surface with a slight texture produced by pressing the finished sheet between cold cylinders. Mainly a term used for watercolor papers. Hot Pressed (smooth) and Rough (heavily textured) are the two other main surface textures.

-

What is a Deckle Edge?The feathery edge of a paper which is the result of the natural run-off of wet pulp when making handmade and mouldmade paper, or the result of sheets being torn while wet. Machinemade papers can simulate a deckle by cutting the wet paper with a water jet on the paper machine.

-

What is Dimensional Stability?The degree to which a paper will maintain its size and shape when subjected to changes in moisture content and relative humidity. Very important in maintaining registration in printing.

-

What is a Felt Finish?Surface characteristics of paper formed at the wet end of a paper machine, using woven wool or synthetic felts with distinctive patterns to create a texture in the finished sheets. Also called felt marks.

-

What is a paper's "formation"?

The arrangement of fibers in a sheet of paper, which can be seen by holding a sheet of paper to the light source. The formation is determined by composition of the fibers, fiber length, machine speed and other factors.

Formation can run from "tight" to "wild" and is a major factor in determining how the sheet will perform, affecting factors like levelness, strength and dimensional stability.

-

What is grain direction?

The direction in which a majority of the fibers lie in a finished sheet of paper. Grain direction is determined by the fibers' alignment parallel with the movement of the paper as it travels through the paper machine.

Why is this important to you? Paper folds much more easily "with" the grain direction.

-

What are Laid Papers?Papers with a "grid" pattern in the sheet, resulting from the pulp resting against wires on the papermaking screen. "Laid" lines are closely spaced wile "chain" lines are farrther apart and run parallel with the grain direction of the sheet.

-

What are Rice Papers?A common misnomer used to describe Asian papers. There are no papers actually made from rice - these papers are typically made of Kozo, Mulberry, Gampi or Mitsumata.

-

Which of your papers are mouldmade?

Of the papers listed on the site, the following are mouldmade:

- Arches

- Arturo

- Fabriano Elle Erre

- Lanaquarelle

- Magnani Acquerello

- Pescia

- Revere

- Somerset

-

Are both sides of paper the same?

All paper has two distinctly different sides. With mould made paper they are called the 'felt' and 'mould' (or 'wire') sides. The 'felt' side relates to the top side of the paper, and gets its name because it touches the natural woollen felt first during manufacture. The 'mould' side in contrast is the side that is in contact with the wire mesh of the cylinder mould that rotates inside the vat of pulp.

The 'felt' side is considered superior to the 'mould' side by many artists and printers as it has a more random pattern associated with it, while the wire side is more regular.

Papermaking

-

What are Cotton Linters?Linters are fibers that adhere to cottonseed after ginning. This byproduct of the textile industry is used as the raw material to produce pulp for cotton fiber content papers. A recovered material, cotton linters would typically otherwise be discarded.

-

What is Mouldmade Paper?

Mouldmade papers simulate the handmade process on a mechanised paper machine. These papers can be mistaken for handmade but there are distinct differences.

The mould is not held by the hand; instead it’s replaced by a slowly rotating cylinder mould, which picks up the paper stock from the vat. The paper is then deposited onto a continuously moving woollen felt.

Mould made paper combines the consistent quality of machine made (fourdrinier) papers, but with the individual character of handmade papers. Mouldmade papers are typically much stronger and flexible than a machinemade paper.

They are of particular interest to artists and printers because of their increased surface strength and beautiful surface texture. Mould made papers won't easily tear because the fibres lay randonly across the sheet, whereas, the fibres in fourdrinier papers tend to lie in one direction, making the sheet weak in this area.

Depending on the grade of paper, one of the characterists of mould made paper can be gorgeous deckle edges.

-

What is Handmade Paper?

To no surprise, this is paper made by hand. The way this is done is by using a "mould" - basically a frame with is covered with a flat rigit screen (western) or flexible screen (asian). In both cases, the mould is covered by a flat frame (called a deckle) to contain the run-off of wet pulp, dipped into a vat of wet pulp, shaken to distribute the fibers evenly and drained of its excess water.

The wet mat of fibers remaining is the newly formed sheet, which is then air dried.

Handmade papermaking can be a totally manual process, involving no electricity. Handmade papers are one-of-a-kind and have four deckle edges.

-

What is Sizing?

The process by which a substance (typically gelatin or starch) is added to paper. Sizing provides resistance to the absorption of moisture and eliminates ink feathering and bleed through.

In the papermaking process, after the sheet is formed, it may be either "surface sized" - pained or brushed onto the surface - or "tub sized" - immersed in a bath.

Paper Measurements

-

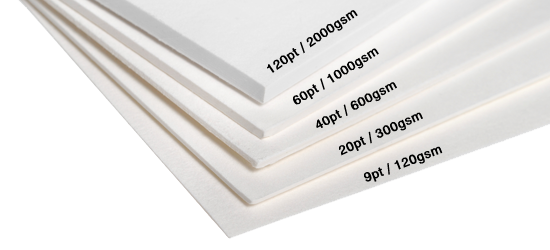

What is paper "caliper"?Caliper is the thickness of a paper measured under specified conditions. Usually expressed in thousandths of an inch (mils). One point, or mil, equals 1/1000th of an inch. Ex. a 15pt sheet is 0.015" thick.

-

What is "gsm"?Gsm = grams per square meter, or the gram weight of a hypothetical square meter of a particular paper.In our opinion, this is the best comparative measure of a paper because it does not vary with sheets size.

-

How do you convert paper weights?In the metric system, the density of all types of paper and paperboard is expressed in terms of grams per square meter (g/m²). This quantity is commonly called grammage. In countries that use United States paper sizes, a less direct measure known as basis weight is used in addition to or instead of grammage. So how do you tell a 300gsm sheet from an 80lb cover? Here's the best online paper weight converter we've seen.

Our Collection

-

I'm looking for the heaviest/thickest paper you have. What are my choices?

Double thick, heavyweight papers are becoming increasingly popular. We have a number of papers from which to choose. Can't decide? Try our new Heavyweight Sampler.

Available for sale here:

- Arturo is available up to 40pt / 600gsm

- Legion Bamboo is available up to 34pt / 535gsm

- Legion Eco Rag is available up to 40pt / 600gsm

- Lettra is available up to 40pt / 600gsm

Available through resellers only:

- Somerset is available up to 500gsm

- Rising Museum Board is available in 4ply (60pt / 1000gsm) and 8ply (120pt / 2000gsm)